Technological advancements and ingenious initiatives deliver greater efficiencies and growth possibilities in the gem and jewellery industry.

This article first appeared in the JNA July/August 2025 issue.

From artificial intelligence (AI), provenance and traceability programmes to innovative diamond solutions, the gem and jewellery industry is embracing technology to enhance operations, offer sophisticated services and meet customer requirements.

Gübelin Gem Lab blazes a trail in leveraging new technology, adopting AI and developing traceability platforms long before these were fully embraced by the trade. And it is not resting on its laurels as it continues to expand the capabilities of its groundbreaking initiatives.

Its AI-powered Gemtelligence, launched in February 2023, can determine the origin of rubies, blue sapphires and emeralds and identify heat treatment in rubies and blue sapphires. The system is integrated in all the lab’s testing protocols in its operations in Lucerne, Hong Kong, New York and Bangkok as well as its mobile laboratories. Every Gemtelligence result though undergoes a plausibility check from a senior gemmologist before it is released.

Gemtelligence was trained on a combination of coloured gemstones from the Gübelin Reference Stone Collection that has over 30,000 stones of high authenticity, and a carefully curated selection of client stones received over the course of more than 100 years. The lab’s database is continually updated and expanded with stones from its field trips, most recent ones being to Tanzania, Vietnam, Pakistan and Madagascar.

Together with the Gübelin Academy, the lab also acquired a collection of more than 1,800 reference samples from its former head of Research, Dietmar Schwarz. After careful analysis and scrutiny, this was likewise included in the training data.

Significant gains

While the most immediate impact of Gemtelligence is greater consistency of results in lab reports, the system also manages to retrieve more information from less data, according to Gübelin Gem Lab Managing Director Daniel Nyfeler.

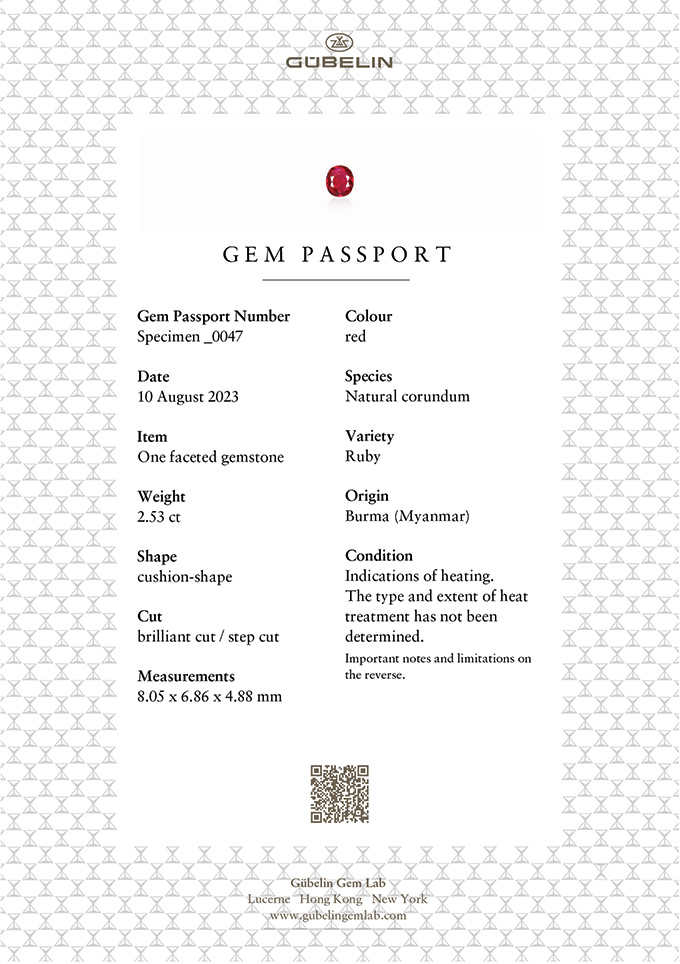

“In some cases, this allows us to shorten the testing protocol. For some stones, we can forgo certain time-consuming microscopic description and/or the expensive chemical analysis by Laser Ablation ICPMS,” he noted. These efficiency gains and cost savings prompted Gübelin Gem Lab to offer the streamlined Gem Passport service and even open a location in Bangkok.

At CHF 200 (around US$243), the Gem Passport provides country of origin and heat treatment determination for rubies, blue sapphires and emeralds of up to 3 carats.

“Owing to the significantly lower cost and the swift turnaround times for Gem Passport, many clients now consider using Gübelin Gem Lab for gemstones of commercial quality,” Nyfeler disclosed. “Also, many of the bigger brands, which buy large volumes of smaller stones, have started to use Gem Passports for stones whose value would not justify the cost of a standard Gübelin Gem

Lab Report.”

According to Nyfeler, Gübelin Gem Lab’s main development project this year is getting Gemtelligence ready for external use. Third parties such as other gem labs or large brands that operate their own labs will be able to use Gemtelligence to interpret data they collect on their stones in their premises.

“We are already speaking to some select laboratories that are keen to partner with us on this. Towards the end of this year, the technology to grant externals access to Gemtelligence should be ready, and third parties can start profiting from the knowledge and expertise contained in the system,” he disclosed.

Companies using the Gemtelligence service can decide whether to disclose their partnership with Gübelin Gem Lab, Nyfeler added.

Traceability for gems

It was also Gübelin Gem Lab that first introduced traceability for coloured gemstones with the official launch of the Emerald Paternity Test in 2017 followed by the Provenance Proof Initiative to track the origin and journey of gemstones. Today, the latter leads tracking and tracing technologies in the coloured gemstone industry with over 40 million gems on the Provenance Proof Blockchain and a community of more than 700 companies.

Provenance Proof, which spun off from Gübelin Gem Lab in 2020, now also encompasses diamonds and jewellery.

“Major diamond manufacturers and jewellery brands have started to apply the nano-tracers from Provenance Proof on melée diamonds and jewellery this year, making true, verifiable supply chain transparency a more standard feature of jewellery,” said Nyfeler.

KGK Suisse SA launched the first DNA-tagged melee diamonds in May. These diamonds are fully verifiable on the blockchain and come with Provenance Proof certificates of origin.

Diamond traceability is indeed gaining momentum in a market seeking greater transparency, with more enterprises adding tracking functionalities to their stones.

In June, Botswana-based rough diamond marketing company, the Okavango Diamond Company (ODC) joined Tracr, the industry-wide diamond blockchain programme developed by De Beers Group.

Wholly owned by the government of Botswana, ODC began registering its rough diamonds in the 3 gram-to-6 gram and 2-carat to 10-carat sizes on Tracr, increasing the availability of traceable diamonds from the country.

Operational ease

In the midstream, ingenious breakthroughs are poised to deliver significant benefits.

Case in point is the Certified Hybrid Diamond Master Set, which is proving a game changer for colour grading. Developed in collaboration with the Accredited Gemologists Association (AGA), Stuller Inc and GCAL by Sarine, this hybrid option combines natural diamonds and lab-grown diamonds (LGDs), providing the trade with cost-effective alternatives to expensive master sets that are difficult to source.

According to Stuller Inc Director of Gemstone Procurement Guy Borenstein, the global availability of essential tools for accurate colour grading has declined significantly due to rising costs and limited supply. This shortage has affected gemmological laboratories, diamond dealers, retailers and appraisers, while impacting consumers who depend on jewellery professionals for expert guidance and accurate grading.

Available from Stuller by end-2025, the Certified Hybrid Diamond Master Sets will comprise seven stones. E-F-G are LGDs while H-I-J-K are natural diamonds.

Borenstein said, “Combining natural and lab-grown diamonds in a single set offers two primary advantages: Greater access to specific colour grades and a significant decrease in cost. All stones will be supplied by Stuller, and the LGDs will primarily be High Pressure High Temperature (HPHT) stones to avoid undesired tints.”

According to Stuller, more than 200 professionals from around the world – including gemmologists, appraisers, gemmological educators, retailers, jewellers and manufacturers – have expressed strong interest in the hybrid master sets, with the list continuing to grow steadily as awareness spreads.

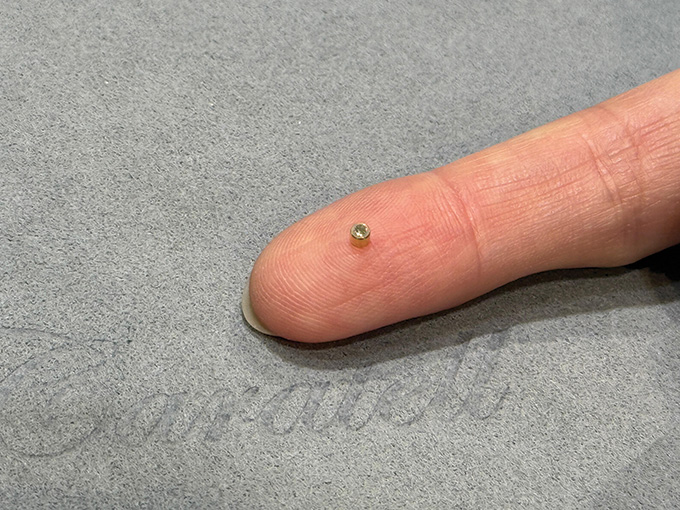

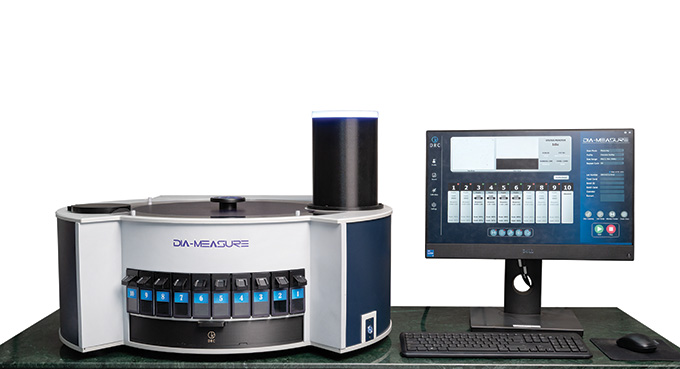

India-based Diamtech Research Centre Pvt Ltd (DRC), for its part, is simplifying the processing of small diamonds.

Its new Dia Measure machine fully automates the measurement, counting, sorting and visual inspection of loose round diamonds, especially of small sizes from 0.90mm to 4.00mm, with micron-level accuracy up to three decimal places (0.005 MM).

Diamtech Research Centre Pvt Ltd CEO Hardik Patel said the machine eliminates key pain points such as manual counting mistakes, inconsistent size profiles, invisible breakage, oval stones in a round batch and time-consuming handling.

The machine detects chipped culets, girdles and shape deviations before final packaging; processes up to 5,500 diamonds per hour, sorted into 10 profiles; and does not require calibration or cleaning.

Developed over a 26-month period, Dia Measure costs US$25,000, with ROI typically achievable in 12 to 18 months, thanks to significant savings in labour, time, and stone damage, said Patel.

“We have had strong interest from current clients who have long expressed the need for automation in diamond measuring and counting,” he continued. “Demand is particularly robust from high-volume jewellery manufacturing firms, diamond melee assortment houses and watch manufacturers.”

Patel revealed that DRC aims to launch fully automated diamond bagging technology by late 2025. Its GEMID Diamond Fingerprint Technology will also soon allow verification even after the diamond has been mounted in single stone studded jewellery.

“This breakthrough is especially useful for retailers with buyback or exchange programmes. When a customer walks in with a jewellery piece, GEMID’s compact desktop unit will instantly identify and match the diamonds to their original registration data – without needing to remove the stones or send them to a workshop. It is a game-changing tool to detect swaps or fraud in seconds and build long-term trust with customers,” he remarked.

On the retail front

De Beers is bringing diamond verification to the retail level too. DiamondProof, which distinguishes natural diamonds from LGDs and diamond simulants, is now available in select retail stores of early adopter customers in the US and India.

According to David Johnson, vice president for Corporate Communications of De Beers Group, DiamondProof’s first production run was relatively limited but will be ramped up based on demand. Stuller is the US sales distributor for the retail-facing device.

“What sets DiamondProof apart from other instruments is the fact that it has been specifically designed to be used on the retail counter to support consumer confidence at the point of sale,” shared Johnson. “With its sleek design, user-friendly interface and large screen, it is perfectly suited to educate consumers about natural diamonds and what distinguishes them from LGDs.”

Consumer engagement is another downstream priority. The “Origin, De Beers Group” branded polished diamond offering enables retailers to tell individual stories of natural diamonds sourced by De Beers, thereby strengthening the connection between a diamond and the individual who wears it.

Consumers will get to explore the details of their diamond’s country of origin and journey through the value chain, supported by the Tracr blockchain platform. They can likewise access information about their unique purchase, including its rarity score and the social impact programmes it has supported. Retailers will be provided with advanced digital tools as well, enhancing consumer engagement through seamless access to provenance information and brand storytelling.

Jewellery narratives

Transparency and traceability extend to jewellery too, thanks to Experloop, the world’s first gold microchip for the certification and identification of jewellery and watches.

Developed by Singapore jeweller Michael Koh, the 2mm round gold RFID microchip is attached to watches and jewellery and can be scanned to retrieve relevant data on the piece’s legacy and story. The item’s owner can access and update their data directly through the Experloop software system.

According to Koh, his main objective is to allow the jewellery piece “to tell its own story.” Since jewellery is often passed down to the next generation or resold, Experloop was created to consolidate the core memories, milestones and complex emotions associated with the piece, together with documentation such as certificates, invoices and important information that can sometimes get lost or misplaced.

First used in Koh’s jewellery creations and sold in his boutique, Caratell, Experloop is now available commercially. “Demand is coming from jewellers, watch and jewellery brands, and insurance companies, with interest from various geographic markets,” said Koh. “Even my previous clients who learned that we now have this technology came back to have their jewellery fitted with the microchip.”

Priced at US$30 to US$35, the patent-pending chip uses passive RFID technology and requires sensory touch activation, which guards against unauthorised scanning. Biometric authentication requirements also ensure that the process is secure.

Experloop also protects against counterfeiting. Noting that global brands lose millions of dollars annually due to the influx of counterfeit goods from the black market, Koh said, “Logos, tags, even serial numbers can be faked, but a microchip with a signal and data that only lives in the Experloop network can be sold and assigned to brands, installed in their pieces, and instantly verify their authenticity and value.”

The chip’s casing is designed for easy assembly into jewellery. It is waterproof, resistant to ultrasonic washing and plating, and can withstand high temperatures of up to 180 degrees Celsius.

“Experloop meets consumer demands for authenticity, provenance and storytelling, while providing a secure and permanent way to store important information,” said Koh. “Companies and brands currently rely on the customer's memory to keep the story alive. Experloop allows all necessary details – including brand information and the customers’ purchase drivers – to be embedded within the jewellery itself.”