Manufacturers of jewellery mountings are taking advantage of rising demand for fancy-shaped diamond mountings alongside stronger preference for lightweight gold products as an alternative to traditional 18-karat gold pieces.

This article first appeared in the JNA November/December 2024 issue.

Jewellery mounting producers are capitalising on changing buyer preferences to sustain the business amid a slowdown in 2024 compared to 2023. According to companies interviewed by JNA, soaring gold prices, a global economic downturn and geopolitical tensions are giving way to new challenges and opportunities in the trade. A stronger focus on high-quality products and unique designs is also critical to promoting growth.

Fancy-shaped diamonds

Türkiye-based jewellery and mounting manufacturer Sina Mounting & Jewellery offers a diverse array of mounting models produced in Istanbul and Dubai for domestic and overseas markets, which include Mexico, Europe, the Middle East, Thailand, Hong Kong and Taiwan.

According to Mehmet Faruk Gürel, export manager of the company, mountings for fancy-shaped diamonds are becoming more sought after in the business, particularly in Asian markets like China, Thailand, Cambodia and Vietnam.

“Clients are showing interest in necklaces featuring marquise, pear-shaped, emerald-cut and baguette-cut diamonds. We target buyers who manufacture high-end jewellery with the aid of our top-quality designs,” he said.

Majority of Sina’s mounting products are handcrafted in 18-karat gold at its factory in Istanbul.

Citing current market conditions, Gürel revealed that clients are now on the lookout for 14-, 10- or 9-karat gold mountings as opposed to the traditional 18-karat gold. As such, the company is considering producing a larger volume of mounting products that are lighter in weight to drive sales. Another interesting development is an increase in the number of Sina’s clients who manufacture lab-grown diamonds (LGDs). Gürel noted that Sina’s client portfolio consists of jewellers who focus on natural diamonds and those who are in the LGD business.

“As a mounting company, I entertain customers from both natural and lab-grown diamond sectors,” he said. “I see this as an advantage since I can cater to both markets. I am also optimistic about further growth in the demand for lab-grown diamond jewellery next year, which will bode well for us.”

Gürel likewise highlighted Türkiye’s rich jewellery making history, with skilled artisans who specialise in intricate designs and traditional craftsmanship. Hence, Türkiye is able to offer an extensive selection of mounting designs to global markets. “We are masters in handmade jewellery products and we specialise in producing lightweight jewellery pieces, thereby fulfilling the unique sourcing needs of a wide range of clients,” he added.

Innovative techniques

Chinese companies are also making a name for themselves in the jewellery mounting sector. Their forte is providing sophisticated and intricate mounting designs, which they achieve through state-of-the-art technology at their factories.

Case in point is Diamond Empress Co Ltd’s innovative production technique that sets it apart from the competition.

“Steel, with its high melting point, retains its shape better compared to plastic moulds. By utilising steel moulds instead of plastic, our mountings achieve a higher level of standardisation, ensuring consistent and uniform shapes,” remarked Zacky Xie, marketing manager of Diamond Empress. “Additionally, we offer mountings for diamonds of various sizes to meet different client orders.”

For over 20 years, Diamond Empress has specialised in the manufacture of 18-karat gold mountings for diamond and coloured gemstone jewellery and semi-finished jewellery using CNC technology, among other techniques. Its primary market is China, with wholesale distribution to Europe, Singapore, Malaysia and Thailand.

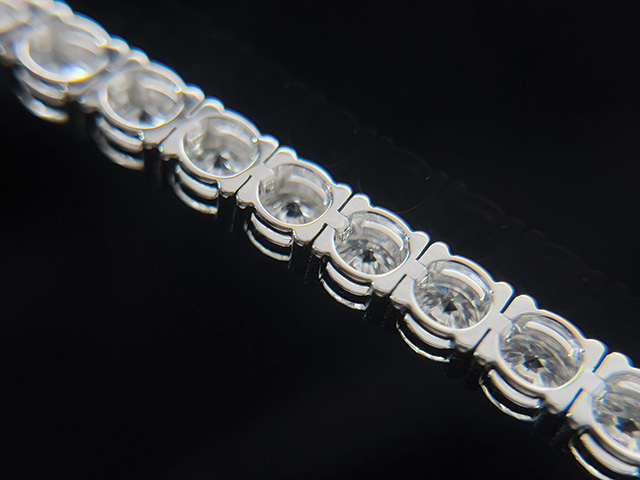

Among Diamond Empress' best-selling items are tennis bracelet mountings, which are sought after for their even and precise alignment that is ideal for flawless gemstone setting. The symmetry and alignment of the stones enhance the overall aesthetic appeal of the jewellery piece while providing comfort, thanks to the smooth edges.

“A tennis bracelet is a classic style. It sells all-year-round and reflects a company’s craftsmanship and dedication to product quality. Best-quality items will always have a strong following in the market,” said Xie. “China is renowned for its cost-effective manufacturing processes, making it a competitive choice for jewellery mountings.”

Design trends

South Korea has also emerged as a rising jewellery manufacturing hub in recent years. One of the companies interviewed by JNA is Echo.Private, an up-and-coming mounting and gold and silver jewellery producer from Iksan, which is becoming known as “the town of gems and jewellery in South Korea.”

Jang HyeonJu, CEO of Echo.Private, underscored the popularity of tennis bracelets and necklaces in South Korea. “Tennis bracelets with butterfly motifs are moving fast. As such, we are focusing on producing better-quality jewellery pieces to fuel sales. For instance, we keep enhancing the clasps used in our tennis bracelets by experimenting with different designs,” Jang said.

The company primarily sells to the domestic market but its aim is to expand its reach across Asia by participating in international jewellery exhibitions.

Meanwhile, Lisa Li, manager of China-based jewellery mounting company Zhu Zhu Bao, said solitaire ring mountings are rising in popularity in China. Faced with a challenging environment, she said the company is looking to tap new opportunities in the Middle East.

Zhu Zhu Bao runs its own manufacturing facility in China where an in-house team produces over 10,000 mounting designs made for gemstone, diamond and pearl jewellery. The company also offers customisation services.

Türkiye-based Mounting Design, for its part, manufactures high-quality mountings at its own production facility. Its focus is on mounting designs inspired by Türkiye’s rich history and tradition. These are specifically targeted towards the domestic market.

Murat Karagülle, general manager of Mounting Design, said chokers are in high demand today as opposed to long chains two years ago.

He noted, “Our mountings are produced with excellent polish, allowing clients to set their own stones without the need for additional polishing. This means that they do not lose more gold during polishing.”

A challenge that jewellery mounting manufacturers face at the moment is buyers increasingly demanding for new mounting designs, Karagülle said. The company is now unveiling fresh designs every six months to keep up with the demand.

“Being situated in Türkiye means we are between Asia and Europe, helping facilitate trade and sourcing of raw materials. This is an advantage that enables us to maintain our business,” said Karagülle.

As the jewellery industry continues to innovate and adapt to changing consumer preferences, one thing remains clear: The art of jewellery mounting is a timeless craft that thrives on creativity, craftsmanship and companies’ ability to meet new demand for inventive products.