Thailand’s Jewelarc International Ltd and India-based Fine were relatively early proponents of the sustainability agenda. As the market increasingly moves towards sustainable options, the jewellery manufacturers strengthen their case with distinctive initiatives and perspectives.

This article first appeared in the JNA May/June 2024 issue.

The drive towards sustainability in the gem and jewellery world truly gained momentum during the pandemic, which sparked public consciousness of Environmental, Social and Governance (ESG) values. Not all companies, however, needed to rush to build their ESG credentials as some had already made these the core pillars of their operations early on. JNA examines the practices of two jewellery manufacturers that place sustainability at the heart of their business.

Green vision

Founded in 2000, Jewelarc International Ltd embarked on a sustainable path pre-pandemic in 2018, continually going the extra mile in its well-thought-out initiatives.

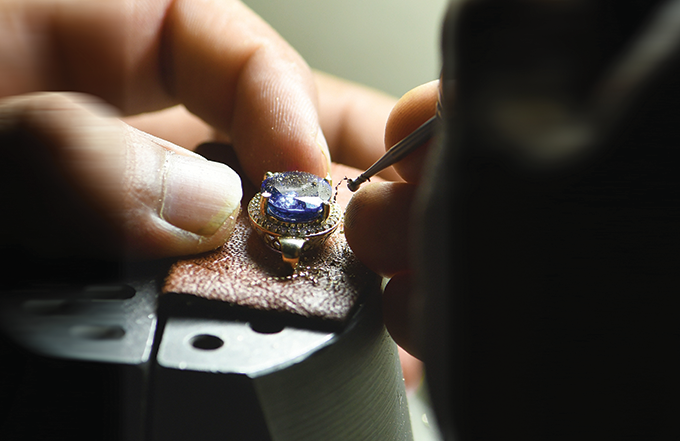

The Thailand-based company produces a wide spectrum of jewellery, from high-value bespoke gem pieces for top jewellery brands to cubic zirconia-studded silver earrings for volume clients. Among its notable creations are The Thalassa necklace with 600 carats of tanzanite; and the Zimbaqua whose aquamarine rough came from the world’s first all-women-run aquamarine mine.

“From the get-go, we have been conscious of our environmental footprint and cognizant of our impact on the planet,” said company managing director Matthew Triglone. “Sustainability came natural to us and always shaped our corporate philosophy.”

Jewelarc operates out of a spacious plastic-free compound that incorporates greenery and al fresco activity and rest areas for employees. Having measured and studied its power consumption, the company has reserved land in the compound to plant trees for carbon sequestration. All its shipments are sent in home-compostable packaging as opposed to bio plastic. The premise is, if the packaging finds its way to a landfill, it will break down completely in eight to 12 weeks with no impact on the environment.

Material concerns

Jewelarc’s environmental stewardship extends to raw materials. Its main objective is not necessarily traceability through blockchain but knowing the source of the materials used in its jewellery. After extensive research on precious metal options, Triglone opted for gold from Single Mine Origin (SMO), which provides responsibly sourced, traceable and mercury-free gold from mines in Mali accredited with the highest social, cultural and environmental standards. Every ounce of SMO gold comes with a QR code that indicates where the gold was mined, the journey it took and the positive impact it has made along the way.

“Unlike most manufacturers keen on sustainability, we do not use recycled gold since this could come from any source that would not meet our ethical standards. It may come from conflict areas or be used to fund wars around the world,” Triglone said. “Instead, all our gold is traceable to a specific mine. And if the order is for recycled gold, we recycle our own gold to maintain a full chain of custody.”

Jewelarc aims to apply the single-mine-origin concept to the rest of the raw materials it uses for its jewellery.

The company plans to exclusively stock only traceable diamonds this year and is currently in negotiations with a source of single-mine-origin diamonds. In the meantime, it buys commercial-grade diamonds from sources that can prove their provenance to two mining regions, Sierra Leone and Botswana, that have strong support programmes for their artisanal miners and their communities.

Jewelarc is also part of and strongly endorses the Provenance Proof blockchain that traces ethically sourced coloured gemstones. And while it currently uses recycled silver, it is scouring the market for single-mine-origin options as well.

Fine pursuits

Similarly taking earth-friendly operations to heart is India-based jewellery manufacturer Fine. In 2019 during the pandemic, the 35-year-old company underwent profound introspection and emerged on the side of sustainability. “All the key players in the company collectively decided we wanted to make the planet better for the next generation,” recalled Abhik Kothari, Fine's vice president, USA Division.

Chief Financial Officer Jignesh Hemani was appointed sustainability officer to lead the company’s ESG efforts. Fine implemented eco-friendly manufacturing processes, switched fully to renewable energy, used recycled metals in all its jewellery, adopted biodegradable packaging and invested in several environmental and community projects, among others.

“We already adhered to responsible business practices before the pandemic, but our transformation in 2019 onwards heralded bigger changes that could truly impact people and the planet for the better,” said Kothari. “We drew up an action plan that identified our big goals year by year and how to achieve these.”

Fine has since planted and nurtured over 10,000 trees in India – fruit-bearing trees in farmlands to help reduce carbon dioxide and provide local families with income; mini forests in rural areas; and carbon sink projects in urban areas for carbon sequestration and to offer shade and reduce air and noise pollution. Also noteworthy are its water management programmes such as the creation and desilting of lakes for the betterment of local communities.

Last year, Fine reduced its operational carbon footprint by 90 per cent, its power consumption by 45 per cent and its water consumption by 70 per cent.

Business realities

While Fine’s transformation into a sustainable jewellery manufacturer started as an internal process towards greater social relevance and fulfilment, it has reaped commercial benefits for the company. Its corporate tagline, “Making jewellery with love for our planet,” reflects its purpose and principles.

“Many of our customers supported our journey and we found more like-minded people wanting to work with us as we moved along,” said Kothari. “Customers that shared our values were interested in our services. Our vision, while internally inspired, became a distinguishing feature for us as a boutique jewellery manufacturer.”

Consumers are increasingly seeking sustainable options, he noted, leading the trade to gravitate towards suppliers that could provide such products. “This push towards sustainability is largely consumer-driven, particularly in key markets such as the US and Europe,” Kothari added.

A member of the Responsible Jewellery Council (RJC) since 2012 under its former name Fine Jewellery Manufacturing Ltd, the company is one of the first three factories in Asia to be RJC-certified for the Chain of Custody (COC) standard.

Trade status

While sustainability is gaining ground in the jewellery industry, Triglone of Jewelarc finds progress to be slow.

He debunked commonly held notions that sustainable practices are an expensive endeavour. “There are no additional charges to being sustainable hence there are no costs to be passed on to customers, making your products more expensive,” he disclosed. “Sustainability is a mindset though. More than obtaining bureaucratic certifications, it is informing the market that you are fully accountable for your impact on people and the planet.”

Fine’s Kothari, however, admits to a cost to sustainability – recycled metals do cost more. “But this is a call we have made, and we are willing to absorb this cost where needed. As a factory, we produce jewellery in recycled metals – there is no way around this,” he said.

Triglone also has mixed feelings about the industry’s dedication to eco-friendly practices. For starters, obtaining clear and comprehensive information about raw materials has been close to impossible, with most online data being out of date and suppliers often half-serious when responding to sustainable enquiries, he said.

The evolution of organisations such as Provenance Proof and SMO has thus been game changers for companies that aim to evolve in an ecologically sustainable way, according to Triglone.

In addition, government agencies, regional gem and jewellery associations, standards-setting organisations and sustainability bodies should work together to improve living, educational and health conditions in smaller mining communities to truly make an impact.

Companies seeking to sincerely embrace responsible manufacturing practices must also fully commit to the cause. “Do not join standards-setting organisations to get their logo on your letterhead. Look at the product category you are in and start reviewing your supply chain. Ask questions; do the research,” Triglone shared. “Trust those you work with on all sides of the transaction. It does not cost more to be responsible.”