Unheated cornflower blue sapphires from Yogo Gulch in Montana are back in the market after more than four decades through a new vertically integrated brand.

This article first appeared in the GEMSWORLD 2024.

A new mine-to-market branding venture of a rare precious resource – unheated cornflower blue sapphires – is a cause for excitement in the gem world, particularly among high-end jewellery retailers and designers in the US.

Yogold Sapphires are becoming the darlings of jewellers not just for their value factors of colour and natural clarity but also for the nostalgic punch they pack. The sapphires hail from an old famous source, the Yogo Gulch igneous dyke near Utica, Montana in the US, discovered in the 1800s during the country’s gold rushes.

During its heyday in the 19th and early 20th century, the mine is reported to have produced millions of carats that were set in engagement rings and bridal jewellery. Designers at Tiffany & Co had a special fondness for the stones, which added to their popularity.

But to the disappointment of sapphire lovers, mining ended in the 1980s, the result of a bankruptcy filing by Intergem, the operator at the time. The mine remained fallow for more than four decades until 2019 when the rights to the mine were acquired by a mining and geology entrepreneur, Jay Edington. With his sons Jerod and Ryan, Jay set up Yogold USA Corp in order to mine, cut and market the sapphires.

Market reentry

Yogold is currently implementing phase one of a three-phase mining plan focused on controlled and orderly expansion over the next five years.

Company president Jerod shared, “At present, we are concentrating on supplying demand in the US, particularly in the state of Montana where most of our current polished production is sold.”

The miner recently entered a semi-exclusive sales and marketing agreement with Riddle’s Jewelry in Rapid City, South Dakota. Riddle’s operates its own jewellery manufacturing facility and sells through 65 stores located in nine US states.

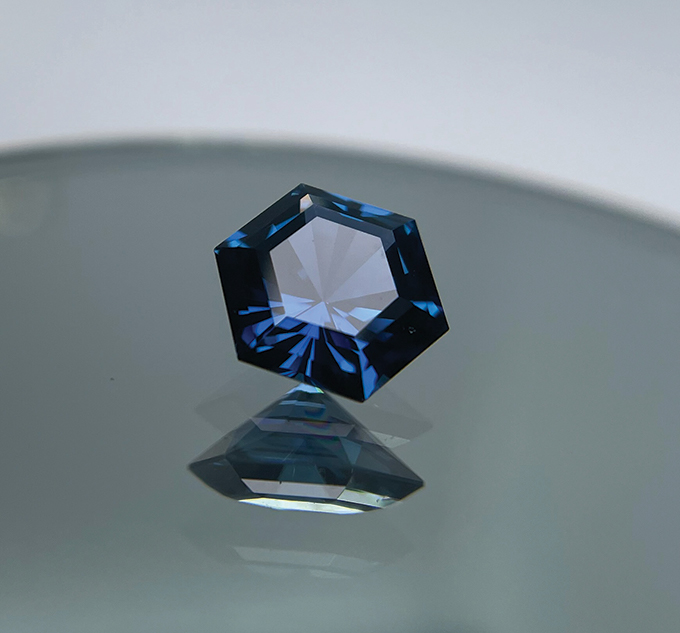

Majority of polished is under one carat but recent discovery of some larger rough – between 5 and 7 carats – is yielding polished up to 2.5 carats, according to Jerod. About 85 per cent is in typical cornflower blue colours while a small percentage is in lavender or purple shades.

“An inherent feature of Yogold sapphires is that colour is evenly distributed and the stones do not require heating to improve colour or clarity,” he explained.

This is the only known deposit in Montana where the sapphires are found within igneous dykes and are in the typical rhombohedral form. These are distinct from sapphires produced in other areas in Montana that are alluvial deposits consisting of water-worn pebbles, and colours tend to be more teals, greens, yellows and bi-colours.

Production and promotions

Yogold has established a cutting facility in Colombo, Sri Lanka to cut its rough production. The facility is managed by Yogold’s vice president for gemstone cutting Amitha Gamage who explained that production is mainly in precise calibrated sizes cut meticulously to ideal proportions with rigorous quality checks implemented at every phase of the cutting. A feature of the polished is that each facet has a mirror polish.

Main production is round brilliants as well as princess cuts and ovals. Sizes of current polished output range from 2mm to 5mm while the number of polished sapphires 1 carat and above is increasing. Average monthly production is between 8,000 and 10,000 pieces, Gamage disclosed.

Part of the company’s branding strategy for the future is to take Yogold sapphires to the global market with a range of Yogold sapphire jewellery.

Yogold also recently concluded an agreement with Colorado-based film production company Mountain Air Productions LLC to create a reality documentary on the renaissance of the Yogo mine. “The episodes will become an important component of Yogold’s global branding and awareness programme,” said Jerod.