The diamond industry’s rapid digital transformation is backed by technological solutions that foster efficiency, productivity and sensitivity to market needs. From Artificial Intelligence and automated grading to traceability through blockchain platforms, technology is bringing a new dimension to the diamond trade.

For the diamond industry, going digital is not just a matter of shifting from the physical to the virtual. It entails adopting new technologies to connect the two worlds, harnessing the best of human expertise and computing power, and taking the international diamond trade to a whole new level with positive social and economic impacts.

Growing social consciousness and technological proficiency are changing consumer priorities as well. Calls for transparency are getting louder and eliciting positive responses. The pandemic meanwhile highlighted the role of Artificial Intelligence (AI) in improving productivity and efficiency. New technology solutions such as AI-based automated grading and blockchain are thus bringing new aspects to the diamond trade.

The World Federation of Diamond Bourses (WFDB) welcomes and supports the new technologies that promote traceability, transparency, security and efficiency in the diamond industry.

“Just as the world diamond industry initiated the elimination of conflict diamonds from the pipeline with the Kimberley Process, it will find the most effective way to implement these technologies for the benefit of the industry and the consumers,” said WFDB President Yoram Dvash.

Data trail

Blockchain solutions to facilitate tracking from mine to market have allowed the diamond industry to enhance its data security, transparency and authenticity while facilitating a more seamless customer experience and enabling easier compliance to stricter standards.

Colin Shah, chairman of India’s Gem & Jewellery Export Promotion Council or GJEPC, noted that consumers are now more interested in the story of the diamonds they purchase, from where they were mined and where they were cut to how they came to market.

“The consumer wants to know the complete journey of diamonds. This is where blockchain technology comes into play as it allows for easy verification of the authenticity of individual stones. The trade is slowly adapting to this new technology, which will boost consumer confidence in diamonds,” he said.

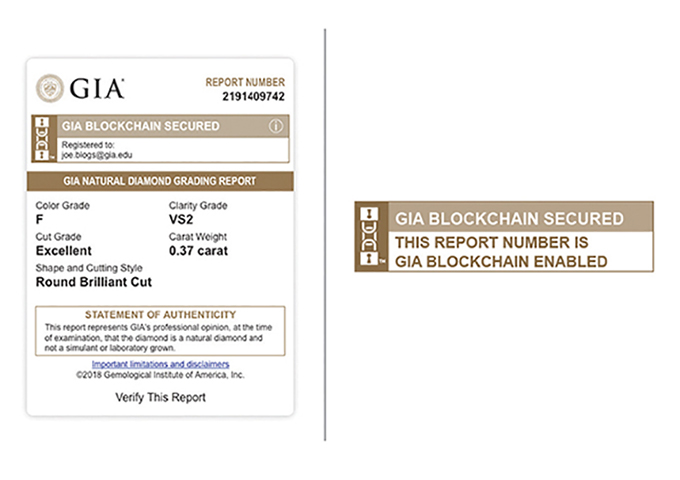

The Gemological Institute of America (GIA) was among the first to use blockchain technology in its grading report.

The benefits of the GIA Blockchain Diamond Grading Report includes a permanent and secure record of grading results, easy digital and secure access to the paperless grading report, and registration of the report to the customer’s email or phone number.

GIA President and CEO Susan Jacques remarked, “We believe that blockchain technology could have broad application to how GIA and our clients manage diamond grading and other reports. The secure blockchain technology delivers secure digital grading information from GIA and provides an additional layer of enhanced consumer trust. This innovation gives consumers the ability to securely track the journey of a diamond or gemstone from mining through manufacturing to designing and retail.”

GIA has worked with leading blockchain technology expert Everledger on several projects. These include the GIA Blockchain Diamond Grading Report, and joint projects with Chow Tai Fook Jewellery Group, and with Chinese e-commerce platform JD.com, using the technology in anti-counterfeiting and tracing programmes to provide customers with independently verified diamond certificates and origin information.

Everledger CEO Leanne Kemp said, “Blockchain is capable of handling virtually the entire e-commerce experience, including payments, product searches, supply chain tracking, loyalty programmes, product reviews, data security, and post-sale customer care.”

She also underscores the relevance of the KYO (Know Your Object) concept in trade applications.

“KYC (Know Your Customer) is fundamentally important across any industry in the world, particularly where banking and financial services are involved. While KYC is a critical point in onboarding our blockchain application, we believe that there's an awakening around product risk calibration, what we call KYO,” Kemp shared. “The work that we have been doing on an object level married with KYC might become a very important next stage step in validating good people doing good business on trustful networks.”

The company’s third-party independent platform provides a secure and permanent digital record of an object's origin, characteristics and ownership across all verticals, from diamonds and gemstones to luxury goods and wines, among others.

Tracr is another end-to-end diamond industry blockchain traceability platform. It was initiated and led by the De Beers Group and built collaboratively with the diamond industry.

Participants range from large producers, artisanal and small-scale miners, and manufacturers to grading laboratories and retailers. Alrosa, Chow Tai Fook Jewellery Group and Signet Jewelers joined Tracr’s pilot programme. With thousands of diamonds being registered every month on the system, Tracr tracks diamonds along the entire value chain.

Keeping track

Growing market interest in the journey of diamonds from mine to market has indeed spawned several traceability and provenance solutions.

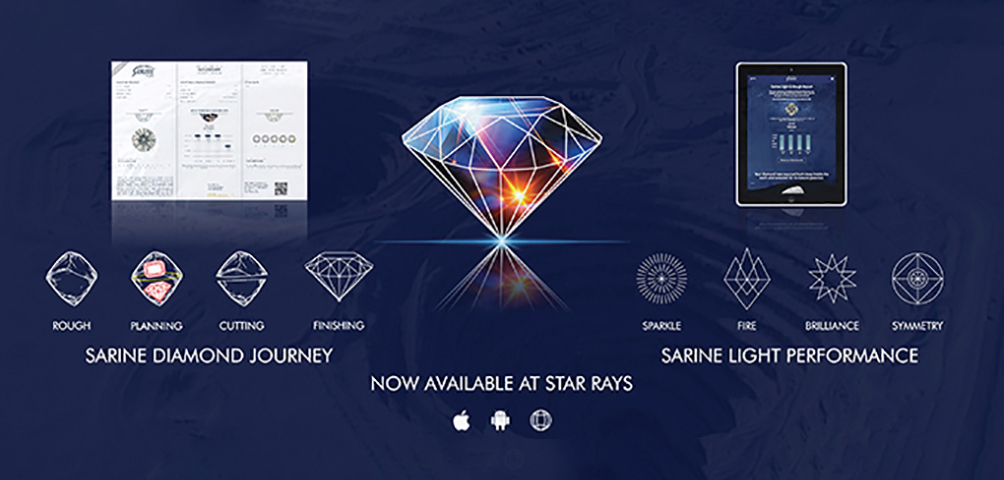

Diamond technology specialist Sarine relies on its ever-expanding portfolio of solutions to trace a diamond’s journey. The Sarine Diamond Journey™ provides a traceability solution from the mine to the different layers along the pipeline all the way down to the retailer and the consumer itself. The initiative leverages the scanning, mapping, planning and analysis technologies that Sarine has implemented in the diamond pipeline over the last 30 years.

The first 23 suppliers in the Sarine Diamond Journey™ have joined Sarine’s Official Partner Program. Long-term partner Star Rays now uses the Sarine Diamond Journey™ traceability to give its customers the complete mine-to-store story behind each unique diamond. To determine the origin of the diamond, Sarine goes to the source: The diamond producer and the mine. The tracking of the diamond commences with a scan of the rough diamond at the mine on one of Sarine's systems, thus creating a rough diamond ‘Birth Certificate’ that can include the country or even the mine itself.

Subsequently, as the diamond passes through the various stages of manufacturing, Sarine's cutting-edge technologies used throughout the midstream collect actual verifiable real-time data pertaining to the scanning, planning and polishing phases, culminating with imagery and data about the final polished stone. Using this rich data that is automatically reported by its systems, Sarine is able to track the diamond along its journey from mine to consumer.

“Traceability entails much more than simply protecting diamond data along the pipeline. For the process to be verifiable, you need verifiable diamond information rather than declarative information. That can only come from objective tech-based solutions that collect and store diamond data with no manual interference, starting from the mine all the way to the consumer,” said Sarine CEO David Block.

Millennial and Gen Z buyers who drive most of the demand for diamonds are willing to pay more and prefer to buy diamonds that have had a positive impact on society and the environment during their journey, according to Rahul Jauhari, Star Rays senior vice president of global sales and marketing.

“Knowing where the diamond was mined and its entire journey before reaching them gives consumers confidence in their purchase. They want to know if a diamond is responsibly sourced and comes from a sustainable environment. Their interest goes beyond the origin of the diamond and into the journey the diamond took to reach them,” Jauhari explained. “Sharing the unique story behind each diamond creates a rich storytelling experience that excites consumers and deepens their bond with a diamond.”

Sarine has already announced cooperation agreements with miners such as Alrosa and Lucara. The traceability solution tracks the diamond from its rough source, including provision of the specific country of origin, through its multiple manufacturing stages and all the way to the final polished diamond.

“Connecting between the physical and the digital is the most critical part of traceability, and is actually the most difficult challenge for our industry. As a diamond goes down from the mine to the consumer, it transforms from a rough diamond to a polished diamond, so you’re not just tracking an object, you’re tracking an object that is actually changing and transforming as it goes down the pipeline,” said Block.

Grading breakthroughs

AI is also opening up new possibilities for the diamond trade, particularly in the field of grading.

Essentially the ability of computers to perform complex tasks, including visual perception, which usually require human intelligence, AI is one of the components that will eventually enable fully automated diamond grading.

Repeatable and independent grading, whether performed by an AI system or experts in a gemmological laboratory, also requires carefully calibrated instrumentation, strict adherence to grading standards and, most importantly, a robust database of diamond grading information as a reference for human grading and to train the AI grading system.

In July 2020, GIA announced it would collaborate with IBM to bring AI to diamond grading. “GIA developed, shares and safeguards the globally accepted standards – the GIA International Diamond Grading System – used by everyone in the diamond value chain, from the mine to retail, to evaluate and communicate the quality of diamonds. We have decades of experience and expertise built on the evaluation of tens of millions of diamonds by thousands of skilled, experienced GIA staff. AI-powered automated grading needs an incredible amount of data. Only GIA has that,” said Pritesh Patel, GIA senior vice president and chief operating officer.

In addition, GIA’s expertise in instrumentation “ensures that no matter where or when a diamond is evaluated by GIA, it can legitimately be compared to all other GIA-graded diamonds,” he continued. The diamond-grading skills of highly trained and experienced gemmologists and graders remain invaluable though. GIA notes that grading large and high-quality diamonds is very complex and will require the insight of GIA’s expert staff. And, while the AI-powered automated grading systems will allow GIA to deliver advancements in consistency, accuracy and speed, the AI will need to learn from skilled gemmologists, researchers and graders to achieve those advancements.

“I can see AI grading having a tremendous impact on our service time. Right now, grading takes two to three days – that does not include shipping and preparation. Our long-term vision is to reduce that dramatically, to just hours or even minutes. Further automation will allow us to set a new bar in diamond grading standards. The benefits to clients and consumers will come from greater consistency and efficiency, and expansion of new services,” commented Patel.

GIA envisions that AI and automated grading will enable on-site grading outside of the GIA laboratories for certain categories of diamonds someday. To maintain the absolute integrity, neutrality and independence of the GIA grading process and reports, the instrumentation will be owned by GIA and operated by highly trained GIA staff to achieve that all-important consistency, and precise calibration and alignment of instruments across all locations.

Automated solutions

Sarine is also moving full steam ahead into AI 4Cs Grading. The company first announced its ability to automate the grading of diamond colour and clarity in 2016. At present, the AI 4Cs and automated Light™ Performance grading operate daily at Sarine AI-based grading labs, which were opened in Israel in 2018 and in India in 2019.

According to Block, the best way to create an automated technology-based grading system is through machine learning. This system mimics the activity of a human grader yet with far more accuracy, consistency, and efficiency. Sarine’s machine-learning technologies basically learn how to grade diamonds in a similar way that a young child learns colours. The child sees the different shades of a specific colour over and over again and refines his or her ability over time to accurately identify the colour and its variations. Sarine’s objective is to create a fully automated process for all the different aspects of diamond grading through technology.

Automated grading uses machine learning to assess the grading results of tens of thousands of diamonds to arrive confidently at its colour and clarity grades. Sarine’s automated 4Cs grading technology was developed as 'GIA compatible' but also with the flexibility of adopting various grading standards.

Block noted that apart from the 4Cs, many other criteria impact the price of diamonds today. These include types of inclusions, their location in the stone and visibility through the table, fluorescence, milkiness, and colour tinge, among others.

AI-based grading technology is advancing to the stage where it will be able to sort goods into additional categories, which will enable much more effective trade between the buyer and seller, and reduce rejections of goods that meet the initial 4Cs criteria, he revealed.

“In the next phase of the diamond grading revolution – Sarine eGrading™ – we will see AI tech-based diamond grading break out of the four walls of the gem lab. Diamond grading will be conducted at source by the manufacturer or wholesaler in their own offices. Systems located at the suppliers will capture the diamond data and then be uploaded to the cloud to analyse and grade the diamond. We believe the market is moving in this direction and our technology is now mature enough to make that happen,” Block said.

The ability to grade at the source eliminates the need to ship diamonds back and forth and cuts back on associated expenses such as insurance and shipping. This will significantly shorten the cycle time thereby saving additional costs. The Sarine eGrading programme is being rolled out on a pilot basis to a number of diamond manufacturers.

Meanwhile, the digital aspect also accommodates special features such as customised diamond reports, which is difficult for traditional labs to achieve. Advanced cloud infrastructure provides access to interactive digital reports so that retailers can offer consumers an engaging omni-channel experience.

Block reported that more and more retailers in Southeast Asia and China, where consumers are by far the most digitally native in the world, are choosing to adopt Sarine AI-based reports.

What is blockchain?

Blockchain is a decentralised stored and distributed ledger that maintains a continuously growing list of records called “blocks,” which are secured from tampering and revision. Blockchain technology is capable of protecting high-value assets with critical data, like diamonds. Diamond grading results recorded on the blockchain are permanent and immutable, ensuring the authenticity and security of the asset’s data.